Q-Pumps® designs and manufactures sanitary industrial pumps designed for different sanitary applications, including the mixing and integration of Xanthan gum.

The food industry is constantly evolving and growing, this is due to the fact that science has been involved in the processes of creating ingredients, food production, improving recipes or finding new ways to manufacture additives and ingredients. Food chemistry has revolutionized the industry, adapting to the requirements of society: responding to illnesses, diseases or characteristics of the population that has more demands regarding a certain type of food.

Such is the case of Xanthan gum, which emerges as a stabilizer, thickener, and emulsifier alternative for hundreds of products, foods, and beverages. In this article we will tell you more about it and what is the best pumping solution.

Such is the case of Xanthan gum, which emerges as a stabilizer, thickener, and emulsifier alternative for hundreds of products, foods, and beverages. In this article we will tell you more about it and what is the best pumping solution.

What is Xanthan gum?

It is a polysaccharide, that is, a complex and larger carbohydrate molecule, with small sugar molecules that are chemically linked to each other, Xanthan gum is obtained from the fermentation of carbohydrates, from corn, produced by the Xanthomonas bacterium Campestris. This, has characteristics that make it especially useful in the process of preparing some foods and as a complement to other ingredients, within the characteristics of Xanthan gum are:

• It is completely soluble in water, whether cold or hot.

• It is completely soluble in water, whether cold or hot.

• It is easy to hydrate, it also produces water retention, giving rise to highly viscous solutions with low concentration.

• It has uniform viscosities, in very extreme temperature ranges, either at freezing or boiling.

•Thermal stability.

• It has good solubility in contact with acids and/or alkaline.

• High resistance to enzymes.

These characteristics improve the sensory experience of food: mouthfeel, taste perception, food consistency, among others.

These characteristics improve the sensory experience of food: mouthfeel, taste perception, food consistency, among others.

What is the origin of Xanthan gum?

Was born from the fermentation of starch from the corn plant, a carbohydrate that gives rise to this polysaccharide. It was discovered around the years 1950-1960 by researchers of the United States Department of Agriculture, who were looking to find new uses for corn. However, it is known that it was not accepted as an additive for the food industry until 1968, in the US, Canada and Europe.

Its discovery was transcendental, since its incorporation into the foo recipes, products, beverages, drugs and cosmetics. It provides benefits of thickness, viscosity, stability, without altering the flavor or color of the liquid in which it is applied.

Its discovery was transcendental, since its incorporation into the foo recipes, products, beverages, drugs and cosmetics. It provides benefits of thickness, viscosity, stability, without altering the flavor or color of the liquid in which it is applied.

What is the use given to Xanthan Gum?

As we have mentioned, this substance has characteristics that give foods high viscosity and pseudoplasticity, together with a low caloric value and ease of dissolving in hot and cold water, provides stability and has a high resistance to variations in PH and temperature. In addition, it does not add flavors or odors, which is why its application can be so diverse:

Beverages

Xanthan gum can be used to give body to drinks and juices from different fruits, it also improves the appearance by helping the suspension of pulps and syrups, it gives drinks good consistency, preserve flavors, and stability even if they spend a long time stored at variable temperatures.

Dairy products

Beverages

Xanthan gum can be used to give body to drinks and juices from different fruits, it also improves the appearance by helping the suspension of pulps and syrups, it gives drinks good consistency, preserve flavors, and stability even if they spend a long time stored at variable temperatures.

Dairy products

Xanthan gum, in combination with other types of gums, such as guar, works as a stabilizer for ice cream, shakes, milkshakes and milk. It works well combined with meticulous, and other substances for frozen dairy products that must preserve their properties. It’s use helps firmness, body and a considerable improvement in the flavor of cheeses, yogurts and sour creams.

Syrups

Syrups

Xanthan gum improves the fluidity and adhesion of syrups to fruits, ice cream, and other foods. They control their runoff and penetration.

Sauces and Dressings

Sauces and Dressings

The use of Xanthan gum provides stability to all types of emulsions, for times of up to one year prior to consumption. It also facilitates mobility and viscous flow within the bottle.

Canned Food.

Canned Food.

The use of gum for canned foods takes advantage of the viscosity of the food to make better cuts and more easily pump mixtures.

Bakery

Bakery

In this industry, Xanthan gum has several uses and applications: to increase water retention during baking, to prolong the shelf life of the product during storage and refrigeration; It is also used to replace the egg in recipes and also to replace the presence of gluten in bread.

There are also other industries besides food industry that use Xanthan gum in their processes:

Pharmaceutical products

There are also other industries besides food industry that use Xanthan gum in their processes:

Pharmaceutical products

It can be used to suspend the active components in medicines, syrup thickener and emulsion stabilizer.

Cosmetics

Cosmetics

Xanthan gum provides stability to the pH of some cosmetics, as well as temperature, salt, acids and other mechanical elements such as cutting and agitation.

Industrial use

Industrial use

This gum can similarly be used as a suspension catalyst, stabilizer and thickener in other applications.

What industries use Xanthan gum?

The current market, at a global level, places Xanthan gum as one of the ingredients that forecasts a compound annual growth rate of about 5.2% by the year 2024, this is mainly due to the fact that the gum fulfills a large number of functions. It also has the necessary hygiene and health certifications to be used for human consumption.

Q-Pumps Pumping Solution for Xanthan Gum: QDB Series

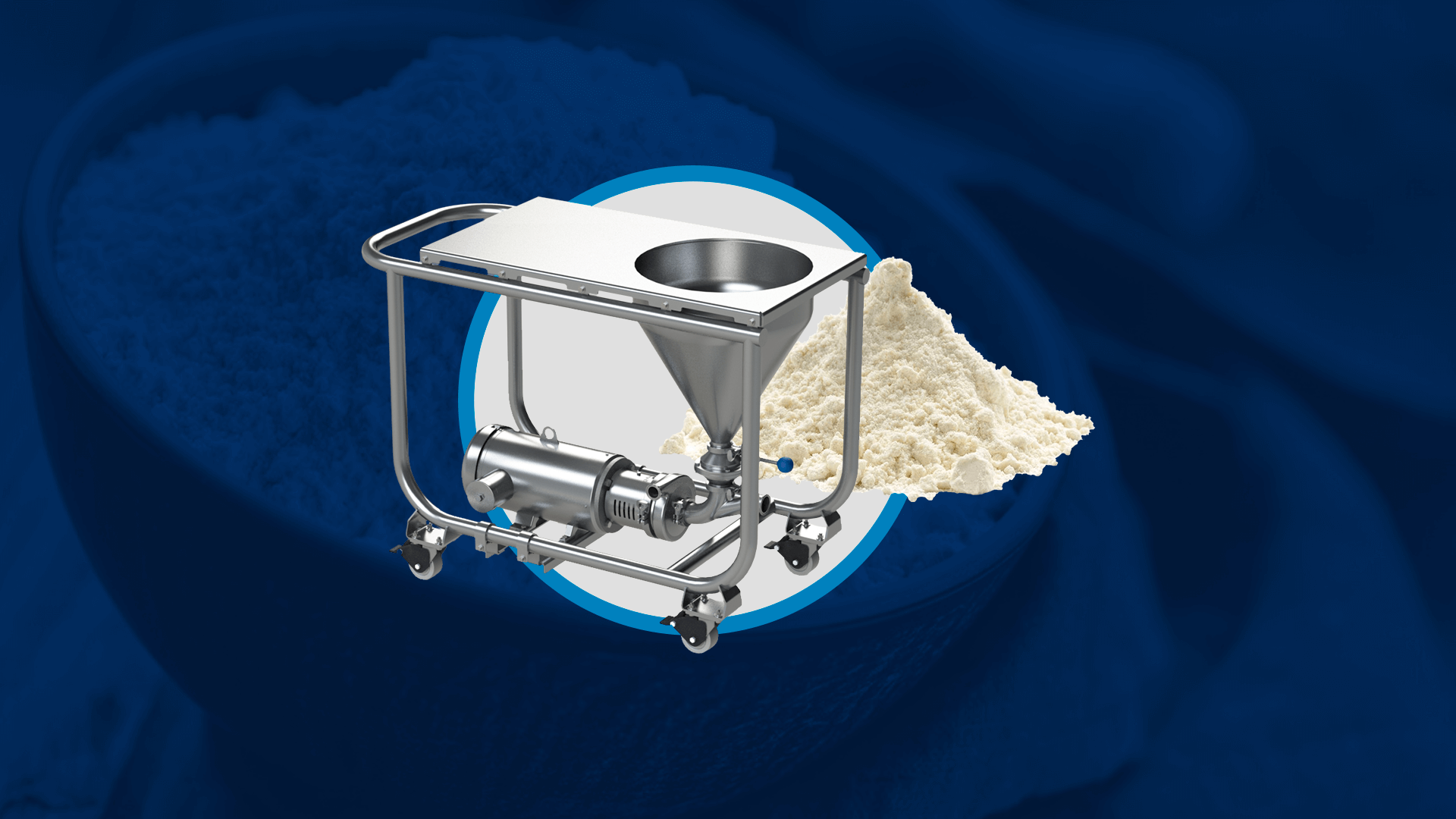

Q-Pumps® designs and manufactures sanitary industrial pumps ideal for different sanitary applications, including the mixing and integration of Xanthan gum with other products for different processes and applications. The Dry Blender or QDB is manufactured as a solution for applications that need to be mixed or disintegrated while being pumped, without losing consistency. With a table integrated, cone and valves to facilitate the operator's tasks, the QDB series stands out as great mixer pump solution for all types of industry.

QDB Pump Reference Data

The main technical data of this pump are:

Flow: 352 gpm / 1,333 lpm

Flow: 352 gpm / 1,333 lpm

Presure: 6 bar / 92 psi

Viscosity: 600 cPs

Temperature: 10º a 150ºC / 14º a 302ºF

QDB pump applications are as follows:

• Homogenization

QDB pump applications are as follows:

• Homogenization

• Mix of powders

• Emulsification

• Addition of flavors

• Disintegration of solids

• Dissolution

Benefits of the QDB pump

• It has a variety of compliments for different types of solids that you can mix.

• It is functional for different solid and gel mixing processes.

• Facilitates its cleaning due to its design.

• It has a ball valve to allow the passage of larger solids and prevent caking.

• Standard seals in SiC/SiC with other options available.

• An attachment kit easily converts a QC+ pump to a QIM or QDB Inline Mixer.

• Facilitates its cleaning due to its design.

• It has a ball valve to allow the passage of larger solids and prevent caking.

• Standard seals in SiC/SiC with other options available.

• An attachment kit easily converts a QC+ pump to a QIM or QDB Inline Mixer.

QDB series pump certificates

The QDB series pump has an sanitary international certification:

3-A Sanitary Standards, Inc.

3-A SSI is an association dedicated to promote the design of hygienic equipment for the food, beverage, and pharmaceutical industries.

It will be a pleasure to engage with you and your production goals. Together we can improve your company's processes through tailor-made pumping solutions.

Learn more about us!: