Q-Pumps® designs and manufactures industrial pumps for various sanitary applications, including the production of antibacterial gel.

It is an essential product today, we find it easily at the entrance of companies and shops.It became a necessity and first response to the health crisis of previous years; however, very few know its origin, its manufacturing process and how this product has given a boost to the pharmaceutical industry.

What is the origin of antibacterial gel?

Despite being a product of daily use, its origin is in the last century. It was in the year 1966, in which Guadalupe "Lupe" Hernández, a nurse of Latin origin, has historically been attributed the creation and elaboration of the first antibacterial gel or hand sanitizer. Lupe Hernández was a nursing student at the University of Bakersfield, in the United States, who saw the need to have clean hands frequently in her day-to-day life, added to the impossibility of having soap and water between each consultation, from this situation the antibacterial gel was born.

Thanks to the chemical properties of alcohol, which is capable of eliminating bacteria, viruses and germs, Lupe Hernández considered it the best hand sanitizer. That same year she patented the invention and the rest is history. This product was first manufactured and marketed exclusively for medical and hospital use, adding invaluable value for medical intervention and hygiene protocols in health centers. But it was not until 20 years later that the first commercial antibacterial gel with the Purrell brand appeared the market.

Antibacterial gel and bacteria, virus, covid and germs

For years, antibacterial gel or hand sanitizer was used only in the medical and clinical field, with little commercial value; however, with the H1N1 swine flu in 2009, this product had a massive growth which was no longer only used in health institutions, but now it was also in the hands of the general public, in a variety of presentations . With an increase in the market of about 70% in just half a year.

Over the years, and the presence of new diseases, antibacterial gel has become a popular and well-known product. Recently, with the new presence of a global virus, such as SARS COVID-19, antibacterial gel has become a necessary product in the daily routine of hygiene and disinfection. In addition, the official information media highlighted antibacterial gel as an antiseptic solution, capable of eliminating germs and the presence of the virus from hands and surfaces. These products became an alternative to reduce the spread of the virus, as long as they contained at least 60% alcohol.

Types of Antibacterial Gel

The product has become so popular that the market has exploited the variety of presentations and ingredients that can be used for antibacterial gel. On the one hand, there are the more commercial versions of the product, which can vary in colors and aromas designed to generate greater well-being than with products that only smell of alcohol. These types of presentations are not the ones used or marketed in hospitals.

There are other gels whose difference are their active components, or in the function they have:

- Broad-spectrum antibacterial gel

Useful to combat viruses, fungi, bacteria and all kinds of germs.

- Antibacterial gel with tricocarban

Made to affect the cell membrane of bacteria.

- Antibacterial gel with triclosan

Made to damage the cell wall of microorganisms.

- Citrus antibacterial gel

Eliminates bacteria, fungi and viruses.

- Chlorhexidine-based antibacterial gel

Broad spectrum, acts on bacteria and some fungi.

- Hand sanitizer with alcohol

The most used alcohols are usually ethyl, propyl and isopropyl and their effect is against bacteria, bacilli, fungi and viruses.

The WHO and its recommendation on antibacterial gel

The World Health Organization created a document called "Guide for local development: WHO-recommended formulations for hand disinfection" where it states that the only fastest way to deactivate and disinfect hands and surfaces is through of alcohol gels. Among the considerations offered to use the antibacterial gel are the following:

1. Thanks to its properties, its effect is broad-spectrum, and it has a minimum risk of generating resistance from bacteria, viruses and germs.

2. It is the best alternative in places where there is no accessibility or availability of water, soap, sinks or other sanitary facilities.

3. Its use is fast, effective and can be frequent without representing a risk to the user.

4. Its use promotes hygiene by being more accessible.

5. Reduces the risk of contracting diseases due to lack of hand hygiene.

6. It minimizes the risk of adverse effects, since it is a safe, acceptable and more tolerated product.

How is an antibacterial gel made?

For its preparation there are various formulas and methods, among the most common is the following, with these ingredients to consider:

– 96% ethanol

– 3% hydrogen peroxide

– Glycerol 98%

– Sterile distilled or cold boiled water

1. The alcohol considered for the amount of product to be produced must be poured.

2. Hydrogen peroxide is added to the mixture.

3. Add the glycerol, this is a viscous substance that can stick to the walls of the container, so it must be cleaned with sterile distilled or cold boiled water before pouring its content into another container.

4. Once the preparation is finished, the lid of the tank must be placed as soon as possible to avoid the evaporation of the alcohol.

5. The solution is mixed again by gently shaking it.

6. The product is distributed in smaller containers that will be used for transportation.

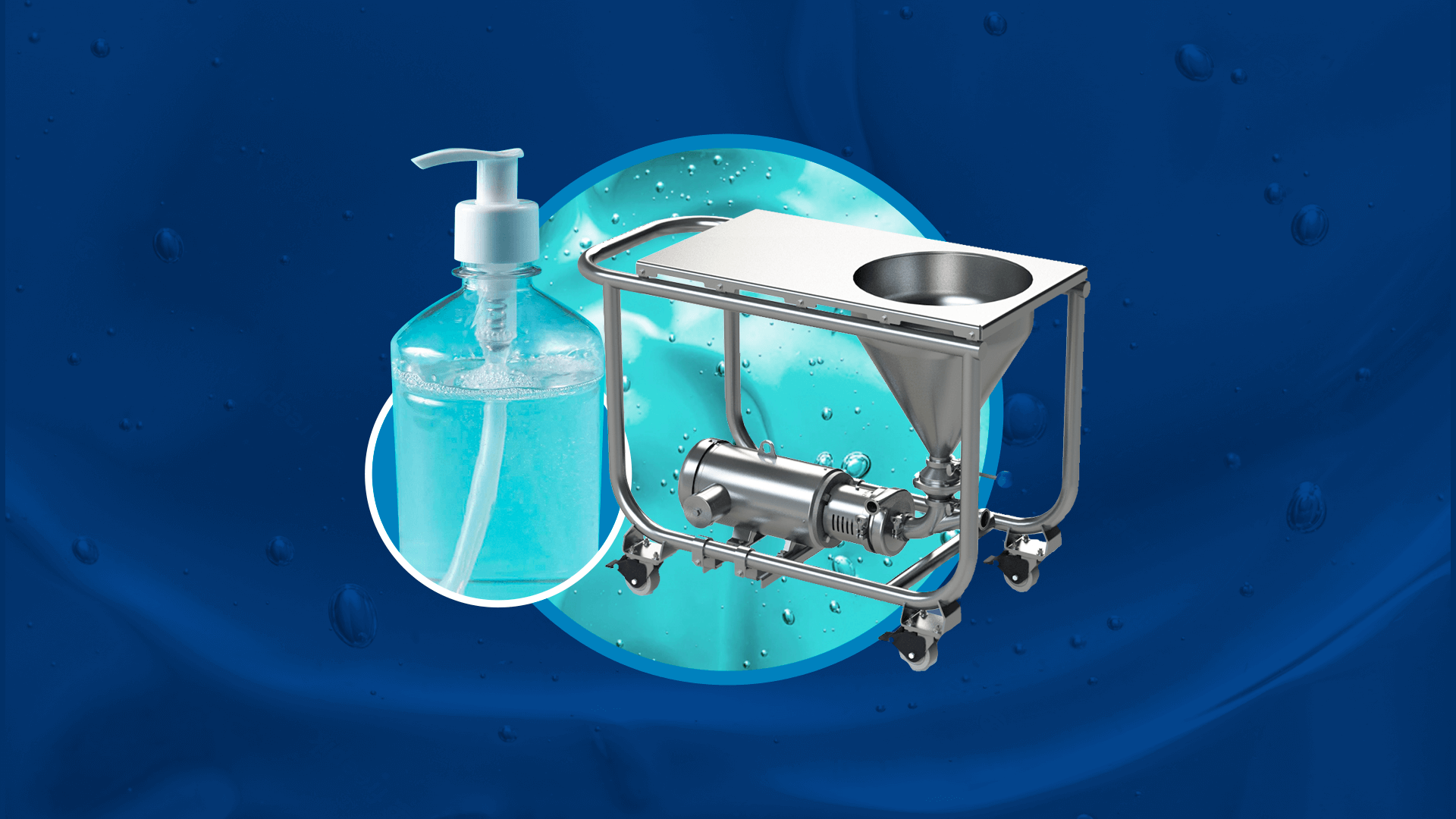

Pumping solutions of Q-Pumps for antibacterial gels: QDB Series Mixer.

Q-Pumps® designs and manufactures industrial pumps designed for various sanitary applications, including the production of antibacterial gel. The Dry Blender or QDB is manufactured as a solution for applications that need to be mixed or broken up while being pumped. With a table with integrated cone and valves to facilitate the tasks of the operator, the QDB series is distinguished by being a practical and versatile equipment.

Advantages of the Series QDB pump in the market:

– It has a variety of attachments for different types of solids that you want to mix.

– It is functional for different solid and gel mixing processes.

– Easy cleaning due to its design

– It has a ball valve that allows the passage of larger solids and prevent caking.

– Standard seals in SiC/SiC with other options available.

– An attachment kit easily converts a QC+ pump to a QIM or QDB Inline Mixer.

QDB pump certificates

The QDB pump has international certifications:

3-A Sanitary Standards, Inc.

3-A SSI is an association that promotes the design of hygienic equipment for the food, beverage, and pharmaceutical industries. Q-Pumps has two certifications: 1004 certified and 1805 certified.

European Hygienic Engineering & Design Group

European Hygienic Engineering & Design Group (EHEDG) is a consortium of equipment manufacturers, food industries, research institutes and public health authorities whose main objective is to promote hygiene during food processing and packaging.

Get in touch with us.

Learn more about the QDB Series:

https://www.q-pumps.com/industrial-pumps/serie-qdb

It will be a pleasure to work together, we can improve your company’s processes through a pumping solution tailored to your needs.

Know more about us.

https://www.q-pumps.com/