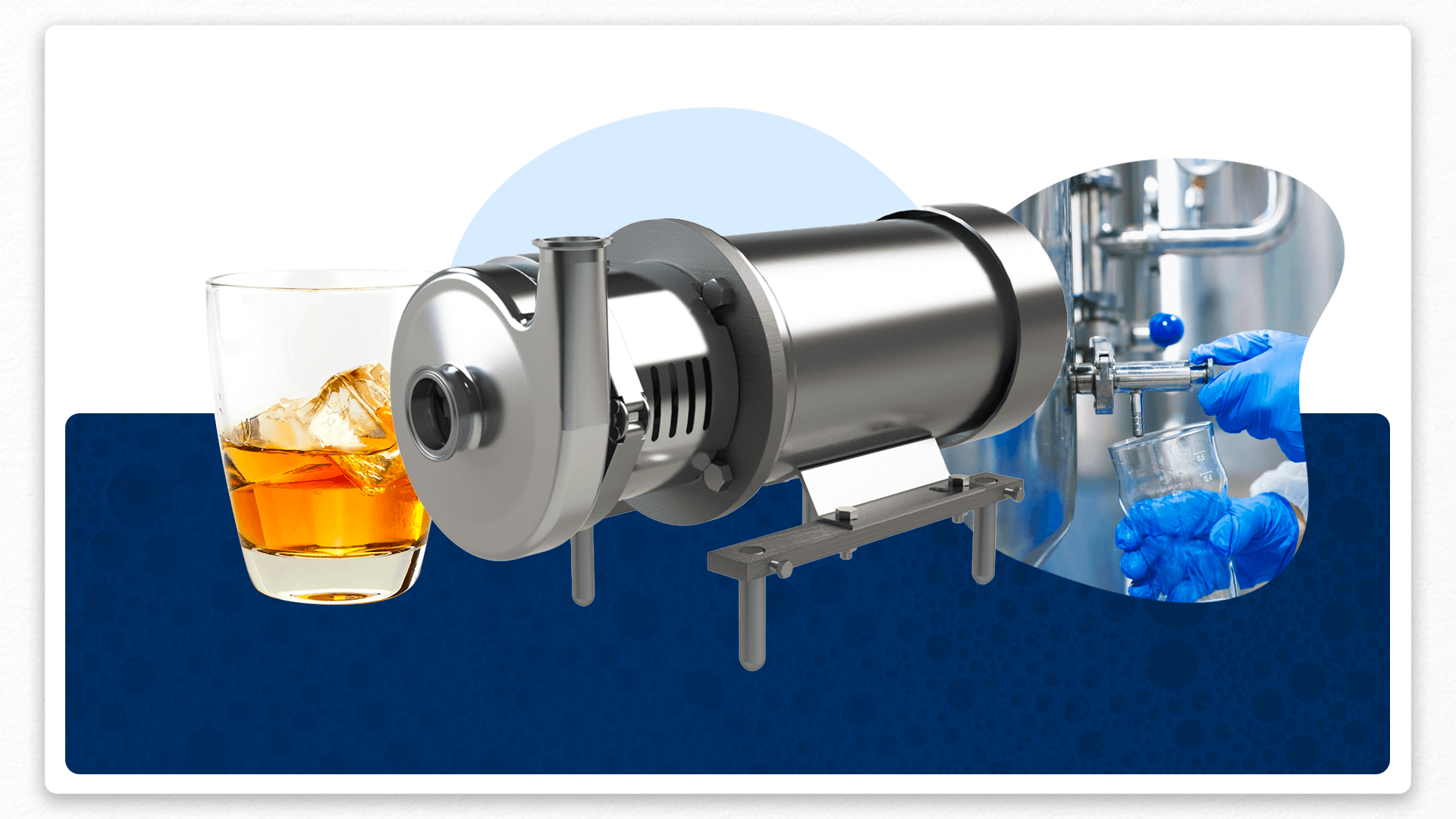

Q-Pumps® designs and manufactures industrial pumps designed for various applications in the alcohol beverage industry, including the preparation, handling and mixing of distillates and liqueurs.

Sanitary industrial pumps for liquors and distillates in the world

Q-Pumps® designs and manufactures industrial pumps designed for different applications in the alcohol beverage industry, including the preparation, handling and mixing of distillates and liquors.

The market and industry for alcohol, fermented foods and liqueurs is as old as history itself, it is one of the most consumed and distributed products in the world; whose manufacturing process has branched out into a wide variety of products for different consumers. There are products such as wine, beer, which we have already talked about in previous articles; However, today we want to talk about liqueurs and distillates and their production process.

The term liquor has been used to describe any alcohol beverage, however, it is worth mentioning that the categorization and name is given in relation to the production process and the ingredients it includes.

The market and industry for alcohol, fermented foods and liqueurs is as old as history itself, it is one of the most consumed and distributed products in the world; whose manufacturing process has branched out into a wide variety of products for different consumers. There are products such as wine, beer, which we have already talked about in previous articles; However, today we want to talk about liqueurs and distillates and their production process.

The term liquor has been used to describe any alcohol beverage, however, it is worth mentioning that the categorization and name is given in relation to the production process and the ingredients it includes.

Difference between liqueurs and distillates

We can define Distillates as beverages with a certain degree of alcohol that are obtained, through a distillation process, this means that it is used a technique which volatile substances are separated from others that are not, in a alembic or a laboratory distiller, by evaporation and then condensation.

The distillates are obtained from the distillation of previously fermented sugary substances. The fermentation of sugars transforms them into alcohol, so when the substances are separated, the liquid remains, which is only alcohol. This category includes only starchy plants. Starchy plants are those that contain starch such as corn, barley and potatoes, which is converted into alcohol.

The result of the previous process is a distilled beverage, that is, with a high alcohol content, which can be processed more than once or even stored for aging.

On the other hand, liquor by definition is an alcohol beverage composed of an ethyl alcohol, a fermented alcohol and additives, or both. For its elaboration, fruits, spices of diverse aromas, sugars, other distillates or even milk cream can be mixed. (Yerko Simunovic's Manual of Alcoholic Beverages). The most recognized liqueurs are usually made based on fruits and herbs.

The distillates are obtained from the distillation of previously fermented sugary substances. The fermentation of sugars transforms them into alcohol, so when the substances are separated, the liquid remains, which is only alcohol. This category includes only starchy plants. Starchy plants are those that contain starch such as corn, barley and potatoes, which is converted into alcohol.

The result of the previous process is a distilled beverage, that is, with a high alcohol content, which can be processed more than once or even stored for aging.

On the other hand, liquor by definition is an alcohol beverage composed of an ethyl alcohol, a fermented alcohol and additives, or both. For its elaboration, fruits, spices of diverse aromas, sugars, other distillates or even milk cream can be mixed. (Yerko Simunovic's Manual of Alcoholic Beverages). The most recognized liqueurs are usually made based on fruits and herbs.

Different distillates all around the world

The most recognized distillates all around the world are the following:

• Whiskey, whose origin is Irish and its production spread rapidly in Scotland, a distillate of cereal and barley.

• Vodka, whose origin is Russian, and its preparation is based on potato distillates.

• Tequila, whose origin is Mexican, whose origin is in the distillation of fermented must obtained from the heart of a plant known as blue agave.

• Rum, it is not clear whether its origin is Asian or South American, its base is the distillate of sugar cane.

• Gin, Dutch drink, whose preparation includes barley, rye and corn distillate, to later add juniper.

Pisco, a distilled beverage of Chilean origin, made with grape distillates.

• Orujo, whose origin is from Spain, a distillate from the skin of the grape.

• Brandy, an alcoholic beverage originally from Holland, which is the distillate of wine and other additives.

• Cognac, a drink originally from France, is also obtained from the distillation of wine and other additives.

The most popular liquors in the world are the following:

• Fruit liqueur, from Italy.• Herbal liqueur, located since Roman times.

• Limoncello, Italian drink.

• Coffee liqueur, whose origin is considered to be the Spanish city of Alicante.

• Pacharán, a drink from the city of Navarra, Spain.

• Amaretto, comes from the city of Saronno, in northern Italy.

• Whiskey, whose origin is Irish and its production spread rapidly in Scotland, a distillate of cereal and barley.

• Vodka, whose origin is Russian, and its preparation is based on potato distillates.

• Tequila, whose origin is Mexican, whose origin is in the distillation of fermented must obtained from the heart of a plant known as blue agave.

• Rum, it is not clear whether its origin is Asian or South American, its base is the distillate of sugar cane.

• Gin, Dutch drink, whose preparation includes barley, rye and corn distillate, to later add juniper.

Pisco, a distilled beverage of Chilean origin, made with grape distillates.

• Orujo, whose origin is from Spain, a distillate from the skin of the grape.

• Brandy, an alcoholic beverage originally from Holland, which is the distillate of wine and other additives.

• Cognac, a drink originally from France, is also obtained from the distillation of wine and other additives.

The most popular liquors in the world are the following:

• Fruit liqueur, from Italy.• Herbal liqueur, located since Roman times.

• Limoncello, Italian drink.

• Coffee liqueur, whose origin is considered to be the Spanish city of Alicante.

• Pacharán, a drink from the city of Navarra, Spain.

• Amaretto, comes from the city of Saronno, in northern Italy.

Consumption of distilled beverages and liqueurs worldwide

According to the World Health Organization, more than half of the population consumes alcohol beverages in only three regions: the European Region with 59.9% of current alcohol drinkers; the Region of the Americas with 54.1%; and the Western Pacific Region with 53.8%.

The lowest percentages of abstinence of alcohol in 2018 were found mainly in countries in Western Europe, North America, Australia and New Zealand, and in Argentina, Chile and Uruguay, in South America. On the other hand, the highest percentages of people who do not consume alcohol are in the countries of North Africa and in the Eastern Mediterranean Region. The differences that can be found in the levels of alcohol consumption between the different regions of the world are due to some sociodemographic variables, such as the rate of abstention, the level of economic development, social and religious customs, culture and the type of alcoholic beverage offered and preferred.

According to information from the OECD, the average annual consumption in OECD countries is equivalent to 9.1 liters of pure alcohol per capita, which is equivalent to two bottles a week. Also, the lowest consumption is observed in Guatemala, Costa Rica and El Salvador, while the highest is observed in Uruguay, Saint Lucia, Argentina and Barbados.

Globally, about 44.8% of the total registered alcohol is consumed as distillates such as those mentioned above. The second most consumed beverage is beer, with 34.3%.

The lowest percentages of abstinence of alcohol in 2018 were found mainly in countries in Western Europe, North America, Australia and New Zealand, and in Argentina, Chile and Uruguay, in South America. On the other hand, the highest percentages of people who do not consume alcohol are in the countries of North Africa and in the Eastern Mediterranean Region. The differences that can be found in the levels of alcohol consumption between the different regions of the world are due to some sociodemographic variables, such as the rate of abstention, the level of economic development, social and religious customs, culture and the type of alcoholic beverage offered and preferred.

According to information from the OECD, the average annual consumption in OECD countries is equivalent to 9.1 liters of pure alcohol per capita, which is equivalent to two bottles a week. Also, the lowest consumption is observed in Guatemala, Costa Rica and El Salvador, while the highest is observed in Uruguay, Saint Lucia, Argentina and Barbados.

Globally, about 44.8% of the total registered alcohol is consumed as distillates such as those mentioned above. The second most consumed beverage is beer, with 34.3%.

Pumping solutions for the different stages of the process: QC series.

Q-Pumps® designs and manufactures industrial pumps designed for various applications in the alcohol beverage industry, including the preparation, handling and mixing of distillates and liqueurs.

The Q-Pumps centrifugal pump is manufactured as a solution for products that need to be mixed while being pumped, they can handle flows up to 1200 GPM and pressure heads up to 270 feet.

QC Series Pump Features

Features an open impeller

• Volute casing with center suction.

• Connections: Clamp (standard), Flange, NPT, Solder, Bevel Seat, DIN, SMS.

• Set of support and legs in stainless steel.

• They can work in both 60 Hz and 50 Hz.

• Stainless steel adapter.

• All parts in contact with the product are made of T316L stainless steel.

Benefits of the QC Series Pump

• The QC/QC+/IC+ Series pumps come with an adapter made of stainless steel and with the option to select between the different types of “D”, “DG” and “E” seals.

• They have a 32Ra (150 GRIT) finish as standard on all surfaces in contact with the fluid, although if necessary other finishes such as electro-polishing and sandblasting are also available.

• Better fastening of the impeller by means of a wedge and a nut.

• Greater long-term efficiency.

• A normal QC series pump can be converted to the QC plus series with a Plus Kit.

QC Series pump sanitary certificates

The QC series pump has international sanitary certifications:

3-A Sanitary Standards, Inc.

3-A SSI is an association dedicated to promoting the design of hygienic equipment for the food, beverage, and pharmaceutical industries. Q-Pumps has two certifications: 1004 certified and 1805 certified.

European Hygienic Engineering & Design Group

European Hygienic Engineering & Design Group (EHEDG) is a consortium of equipment manufacturers, food industries, research institutes and public health authorities whose aim is to promote hygiene during food processing and packaging.

Get in contact with us.

Learn more about the QC Series

Learn more about the QC Series

It will be a pleasure to commit to you and your production goals, together we can improve your company's processes through a pumping solution tailored to your needs. We help you take your company to another level!

Learn more about us!: